Wenn es um Isolationsmaterialien geht, insbesondere für Hochtemperaturumgebungen, sind Flexibilität und leichte Eigenschaften genauso wichtig wie die thermische Leistung Glasfasernadelmatte Bieten Sie eine ideale Lösung für Branchen, die sowohl eine einfache Installation als auch einen zuverlässigen Wärmeschutz benötigen Diese Matten für extreme Bedingungen entwickelt und bieten eine außergewöhnliche Isolierung, ohne das Gewicht oder die Flexibilität zu beeinträchtigen Seien Sie ● S untersuchen, wie Glasfasernadelmatten Ihren Anforderungen an eine leichte, flexible Isolierung erfüllen können und wie sie in verschiedenen realen Anwendungen abschneiden

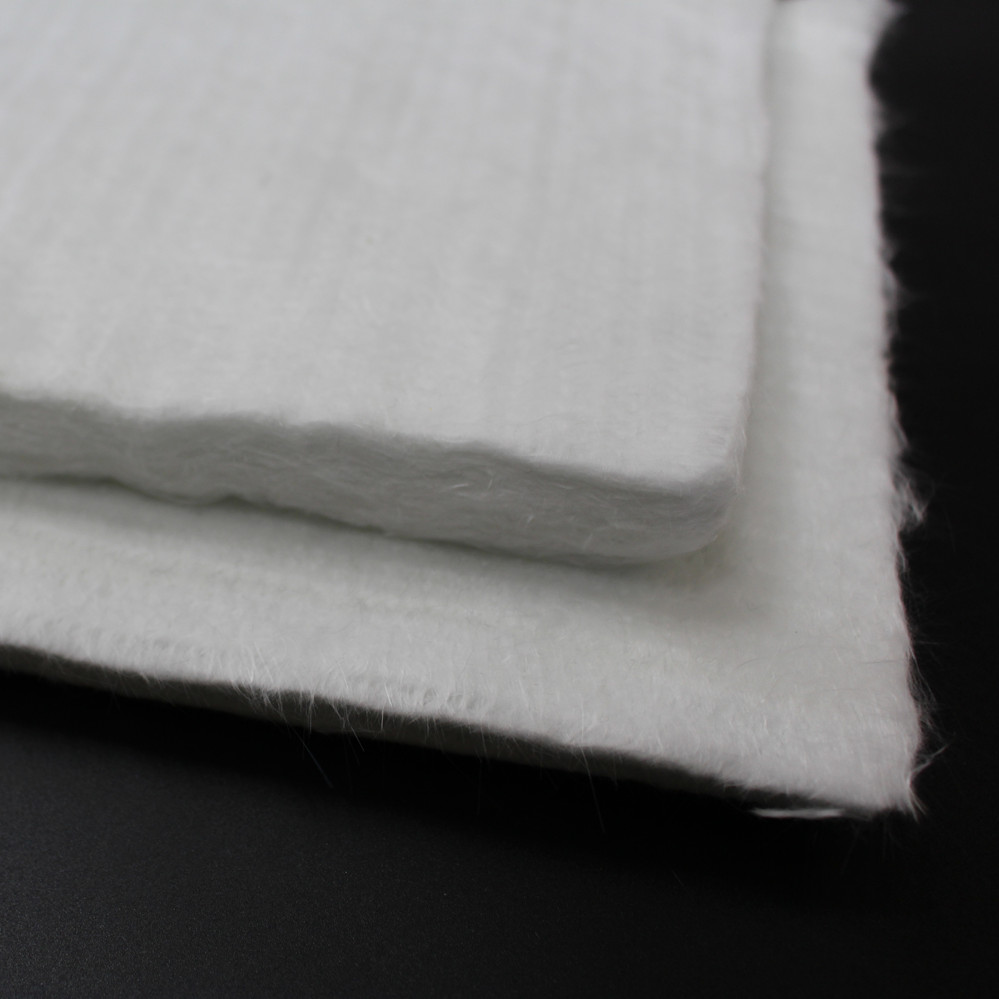

Glasfasernadelmatten bestehen aus kontinuierlichen Faserfasern, die mechanisch zusammengepackt sind und eine dichte, aber flexible Matte erzeugen Dieser Prozess führt zu einem Material, das nicht nur leicht, sondern auch hochwirksam in der Isolierung gegen Hitze, Schall und Abrieb ist Diese Matten kombinieren das Beste aus beiden Welten: Sie bieten einen robusten thermischen Schutz und sind gleichzeitig leicht zu handhaben, zu installieren und zu warten

Leicht und leicht zu handhaben: Eine der herausragenden Merkmale von Glasfasernadelmatten ist ihr niedriges Gewicht, was es im Vergleich zu anderen schwereren Isolationsmaterialien leichter zu transportieren, zu schneiden und zu installieren kann Dies reduziert die Arbeitskosten und die Installationszeit, insbesondere wenn sie in engen oder komplexen Räumen arbeiten

Hohe Flexibilität: Trotz ihrer ausgezeichneten Isoliereigenschaften bleiben diese Matten flexibel, was sie ideal zum Wickeln von Rohren, Kanälen oder unregelmäßig geformten Komponenten macht Diese Flexibilität sorgt dafür, dass eine engagierte und effektive thermische Isolierung in einer Vielzahl von Anwendungen und die Verringerung von Lücken und Wärmeverlust reduziert wird

Ausgezeichnete Wärmelisierung: Glasfasernadelmatten sind so konstruiert, dass sie hohen Temperaturen, oft bis zu 1.000 ° F (538 ° C), standhalten und die Wärmeübertragung effektiv minimieren Ihre Fähigkeit, die thermische Effizienz unter harten Bedingungen aufrechtzuerhalten, macht sie in industriellen Anwendungen von unschätzbarem Wert

Haltbarkeit: Diese Matten bieten einen lang anhaltenden Schutz vor Hitze und Abrieb, um sicherzustellen, dass sie weiterhin in Umgebungen mit hohem Stress abschneiden, ohne sich im Laufe der Zeit zu verschlechtern

Ungiftig und sicher: Fiberglasnadelmatten aus inerten Materialien sind ungiftig und sicher zu bedienen, was sie in vielen Anwendungen zu einer bevorzugten Wahl macht, von der Automobilfunktion bis hin zu Industrie bis zu Bau

Abgassysteme: In der Automobil- und Meeresindustrie werden Glasfasernadelmatten üblicherweise zur Isolierung von Abgassystemen verwendet Ihre leichte Natur macht sie ideal, um sich um Rohre, Verteiler und Turbolader zu wickeln Die Flexibilität dieser Matten stellt sicher, dass sie nahtlos in komplexe Auspuffkonfigurationen passen, effektiven Wärmewiderstand und das Risiko einer Wärmeschäden in der Nähe der nahe gelegenen Komponenten sorgen

Industrieisolierung: Glasfasernadelmatten werden häufig in Hochtemperatur-Herstellungsumgebungen wie Metallgießereien, Keramik und Glasproduktion verwendet Mit ihren leichten und flexiblen Eigenschaften können sie leicht in schwer zugänglichen Bereichen wie Ofenauskleidungen oder Ofen installiert werden, in denen Raum- und Gewichtsbeschränkungen von entscheidender Bedeutung sind

Wärmeleitbarrieren in der Luft- und Raumfahrt: Die Luft- und Raumfahrtindustrie verwendet Glasfasernadelmatten, um empfindliche Geräte und Komponenten vor extremer Hitze zu isolieren Ihre Flexibilität sorgt dafür, dass sie auf eine Vielzahl von Formen und Größen angewendet werden können, sei es ● S auf Abgabesystemen oder Wärmeschildern für Motorkomponenten

Rohrisolierung: In chemischen Pflanzen, Raffinerien und Kraftwerken bieten Glasfasernadelmatten eine hervorragende Lösung für die Isolierung von Hochtemperaturrohren Das leichte Design ermöglicht eine einfache Verpackung und sorgt für eine enge, sichere Isolierung, verringert den Wärmeverlust und die Steigerung der Energieeffizienz

Feuerfeste und thermischer Schutz: Glasfasernadelmatten werden verwendet, um in Wohn- und Gewerbegebäuden feuerfest zu sein Sie sind leicht an Wänden, Decken und anderen kritischen Strukturen zu installieren, bieten passiven Brandschutz und helfen bei Bränden Die Flexibilität der Matten ermöglicht es ihnen, den Konturen verschiedener Oberflächen zu entsprechen und die vollständige Abdeckung zu gewährleisten

Reduzierte Arbeitskosten: Die Kombination aus geringem Gewicht und Flexibilität bedeutet, dass für die Installation weniger Aufwand erforderlich ist, wodurch die gesamten Arbeitskosten gesenkt werden Diese Matten können leicht geschnitten und so geformt werden, dass sie den gewünschten Bereich anpasst, wodurch der Installationsprozess optimiert wird

Raumsparende: Ihr niedriges Profil macht Glasfasernadelmatten zu einer idealen Option für Anwendungen, bei denen der Speicherplatz eine Prämie ist Im Gegensatz zu sperrigen Isolationsmaterialien bieten sie einen effektiven Wärmeschutz, ohne übermäßigen Platz einzubeziehen

Vielseitigkeit: Egal, ob es ● S isolierende Kfz -Abgas, Rohre, Industrieausrüstung oder als feuerfeste Barrieren im Baubereich dienen, Glasfasernadelmatten bieten in verschiedenen Branchen eine unübertroffene Vielseitigkeit

Haltbarkeit mit leichter Wartung: Diese Matten sind nicht nur langlebig, sondern erfordern auch minimale Wartung Ihre widerstandsfähige Struktur sorgt dafür, dass sie im Laufe der Zeit auch in anspruchsvollen Umgebungen weiterleiten und nach Bedarf leicht ersetzt oder angepasst werden können

Kostengünstige Lösung: Trotz ihrer hohen Leistung bieten Glasfasernadelmatten eine wirtschaftliche Lösung für die Hochtemperaturisolierung Ihre leichte und flexible Natur senken sowohl die Transport- als auch die Installationskosten und bieten einen langfristigen Wert für Branchen, die sich auf Kosteneffizienz konzentrieren

Glasfasernadelmatte ist die ideale Wahl für Branchen, die nach einer leichten, flexiblen Isolierung suchen, die die Leistung nicht beeinträchtigt Ihre Fähigkeit, in komplexe, enge Räume zu passen und zuverlässigen Wärmewiderstand zu liefern, macht sie in Anwendungen wie Kfz -Auspuffisolierung, Industrieofenauskleidungen, Rohrisolierung und feuerfestem Mit exzellentem Wärmeschutz, einfacher Installation und langfristiger Haltbarkeit bieten Glasfasernadelmatten eine intelligente, kostengünstige Lösung für den Umgang mit hohen Temperaturherausforderungen

Wenn Sie Ihre Isolationssysteme mit einem Material verbessern möchten, das sowohl leichte als auch flexible Fasernadelmatten die ideale Wahl sind Kontaktieren Sie uns, um mehr darüber zu erfahren, wie diese Matten Ihren Vorgängen helfen und die Leistung erhalten, die Sie von Ihren Wärmeisolierungslösungen benötigen.